3D printed items can be shipped in as fast as 24 hours! MJF, SLS, and FDM Expedite Upload Your 3D File

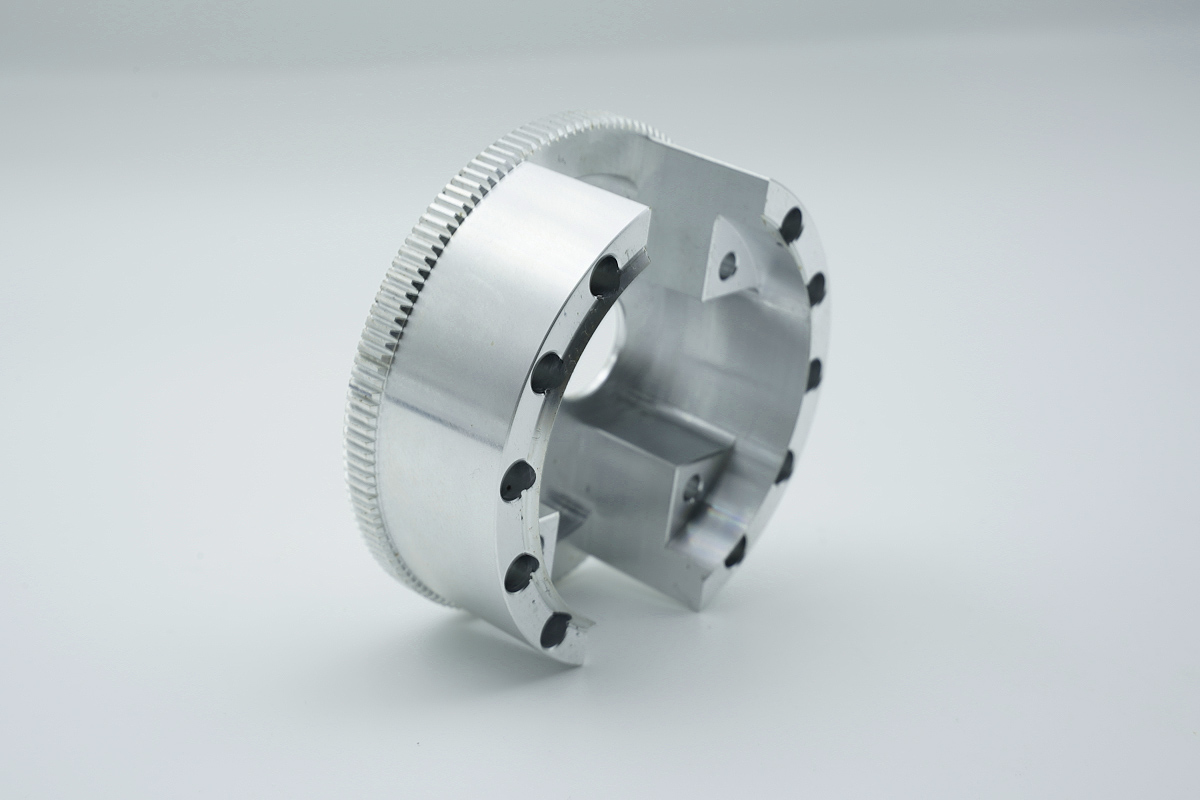

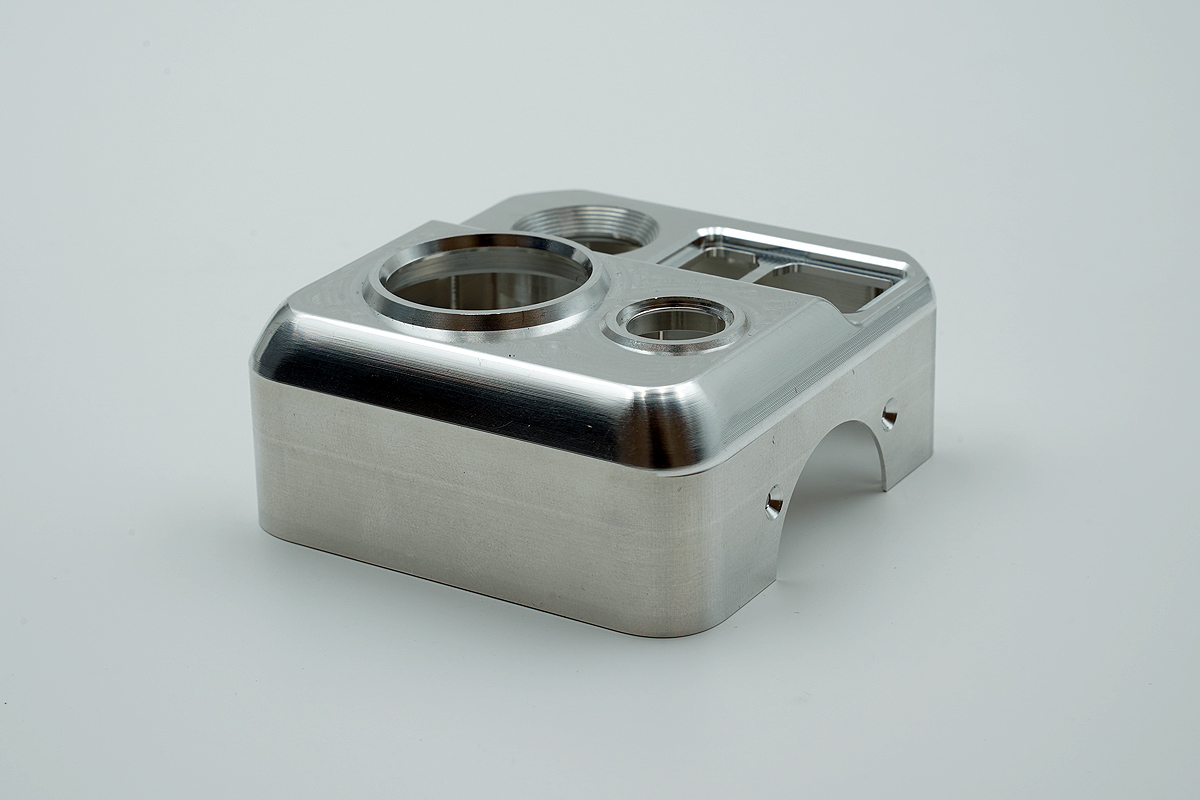

In the realm of CNC machining, 6061-T2 aluminum stands out due to its exceptional mechanical properties, corrosion resistance, favorable weldability, and casting characteristics. However, in practical applications, 6061-T2 aluminum also encounters several challenges and limitations.

Firstly, the strength of 6061-T2 aluminum poses difficulties in precise control and positioning, especially when high precision and complex shapes are required. Therefore, when utilizing 6061-T2 aluminum, it is crucial to ensure adequate mechanical support and fixtures to guarantee processing quality and stability.

Secondly, 6061-T2 aluminum is sensitive to heat, prone to deformation and oxidation. Exposure to high-temperature processing or prolonged air exposure may lead to surface hardening and discoloration issues. To mitigate these problems, it is advisable to adopt appropriate preprocessing measures such as chemical polishing, electroplating, or coating prior to processing.

Furthermore, given its excellent workability and toughness, special care must be taken during processing to prevent cracking or deformation. Operations like cutting, drilling, and grinding can all impact the material's quality and appearance.

To maximize the potential of 6061-T2 aluminum while minimizing potential risks and issues, it is recommended to consider suitable processing techniques and technologies during the design phase to achieve optimal results. For specific application scenarios, professional consulting advice can be sought to better understand and harness the material's characteristics and limitations.

In summary, while 6061-T2 aluminum is a highly valuable material in CNC machining services, it is essential to be aware of its properties and limitations when using it in practical applications. Proper planning of processing procedures and parameters can yield the best possible processing outcomes.