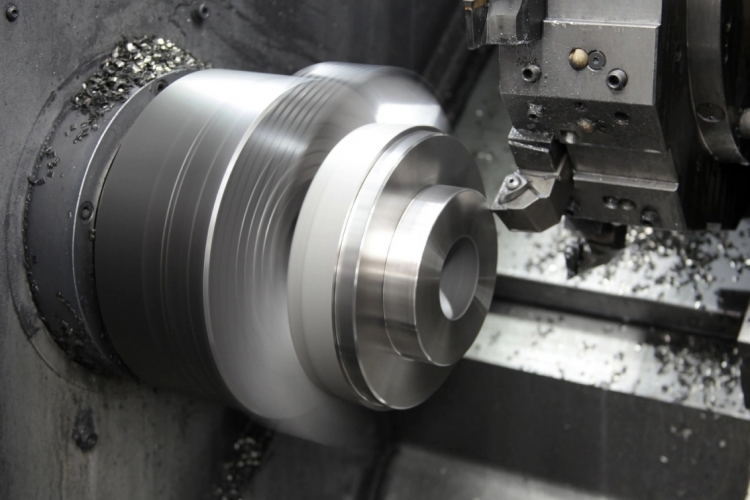

CNC turning service

Source high-performing parts in more than 50 different metals and plastics via our network of advanced CNC turning experts. Tight tolerances available, down to ±.0008"

Order CNC machined Services partsAll uploads are secure and confidential.

en

en